The 11th Edition of Basic Technical Mathematics with Calculus SI Version offers a comprehensive‚ full-color approach to technical math‚ integrating algebra‚ trigonometry‚ and calculus for STEM fields.

Key Features of the 11th Edition

The 11th Edition features a full-color design‚ enhanced pedagogy‚ and relevant applications based on user feedback‚ with contributions from new co-author Rich Evans‚ improving clarity and engagement.

Full-Color Design and Enhanced Pedagogy

The 11th Edition of Basic Technical Mathematics with Calculus SI Version features a vibrant full-color design that enhances student engagement and understanding. The text incorporates high-quality visuals‚ including detailed graphs‚ diagrams‚ and illustrations‚ to simplify complex mathematical concepts. Enhanced pedagogy includes color-coded boxes‚ warnings‚ and tips‚ which highlight critical information and potential areas of confusion. This visually appealing format helps students focus on key ideas and retain information more effectively. The full-color layout is particularly beneficial for technical and STEM fields‚ where visual representation plays a crucial role in problem-solving. By combining aesthetics with functionality‚ this edition creates a more immersive and effective learning experience for students.

New Co-Author Contributions and Revisions

The 11th Edition of Basic Technical Mathematics with Calculus SI Version introduces significant contributions from new co-author Rich Evans. His input has brought fresh perspectives and improvements‚ particularly in enhancing the relevance of applications based on user feedback. The revisions aim to better align the content with the needs of modern technical and STEM students. Chapters have been updated to include more practical‚ real-world examples‚ making the material more relatable and applicable. Additionally‚ the incorporation of new problem sets and updated figures reflects a commitment to maintaining the text’s reputation as a leading resource in technical mathematics education. These changes ensure the book remains current and effective for today’s learners.

Relevance and Applications Based on User Feedback

The 11th Edition of Basic Technical Mathematics with Calculus SI Version places a strong emphasis on real-world applications‚ driven by user feedback. This edition incorporates numerous practical examples from engineering‚ physics‚ and technology to illustrate how mathematical concepts are applied in professional settings. Chapters now include scenario-based problems that mirror on-the-job challenges‚ making the content more engaging and relevant for students in technical fields. The integration of industry-specific case studies and updated exercises ensures that learners can connect theoretical knowledge with practical skills. This approach not only enhances understanding but also prepares students to tackle real-world problems effectively‚ making the text indispensable for STEM disciplines.

Chapter Breakdown and Content Overview

The 11th Edition provides a structured progression from basic algebra and geometry to advanced calculus‚ ensuring a comprehensive understanding of technical mathematics. Chapters cover essential topics such as algebraic operations‚ functions‚ trigonometric principles‚ systems of equations‚ quadratic equations‚ exponents‚ radicals‚ vectors‚ and calculus fundamentals. The text emphasizes practical applications‚ preparing students for real-world problem-solving in STEM fields. Each chapter builds on previous concepts‚ fostering a logical learning path. The inclusion of detailed graphs‚ tables‚ and examples enhances clarity and reinforces theoretical concepts with practical relevance. This organized approach ensures students gain a solid foundation in technical mathematics.

Algebraic Operations and Geometry

This chapter provides a foundational understanding of algebraic operations and geometric principles. It covers essential topics such as real numbers‚ inequalities‚ properties of operations‚ and the solution of linear equations. The section on geometry includes points‚ lines‚ angles‚ and planes‚ with an emphasis on practical applications in technical fields. Students learn to manipulate algebraic expressions‚ solve equations‚ and graph linear and non-linear relationships. The chapter also introduces basic geometric figures‚ their properties‚ and measurements‚ including perimeter‚ area‚ and volume. Practical examples and exercises ensure that students can apply these concepts to real-world problems. This chapter serves as the cornerstone for more advanced topics later in the textbook‚ ensuring a solid mathematical foundation.

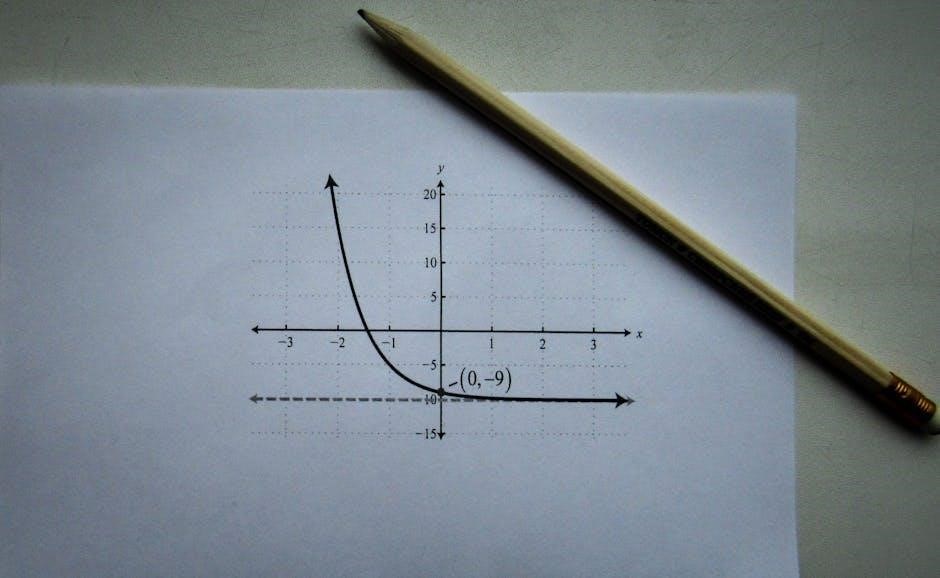

Functions and Graphs

This chapter focuses on understanding functions and their graphical representations‚ essential for technical mathematics. It covers various types of functions‚ including linear‚ quadratic‚ and polynomial‚ with detailed techniques for graphing. The section emphasizes interpreting function behavior‚ such as increasing/decreasing intervals‚ concavity‚ and rates of change‚ which are foundational for calculus. Practical examples illustrate how functions model real-world phenomena in STEM fields. Additionally‚ the chapter explores inverse functions and piecewise-defined functions‚ common in engineering and technology. By analyzing graphs‚ students learn to identify key features like intercepts‚ vertices‚ and asymptotes. Exercises and applications help students master these concepts‚ which are critical for advanced problem-solving in technical and scientific contexts. This chapter bridges algebraic and calculus-based reasoning effectively.

Trigonometric Functions

This section introduces trigonometric functions‚ focusing on their definitions‚ properties‚ and applications in technical mathematics. It begins with the basic trigonometric ratios—sine‚ cosine‚ and tangent—exploring their relationships with angles and triangles. The unit circle is emphasized as a fundamental tool for understanding trigonometric functions beyond right triangles. Students learn to analyze periodic behavior‚ inverse trigonometric functions‚ and applications in various fields like engineering and physics. Graphical representations of sine‚ cosine‚ and tangent functions are also covered‚ highlighting their importance in modeling periodic phenomena. Practical examples and exercises help solidify understanding‚ preparing students for advanced problem-solving in STEM disciplines. This chapter bridges foundational trigonometry with its practical uses in technical and scientific contexts.

Systems of Linear Equations and Determinants

This chapter explores the methods for solving systems of linear equations‚ emphasizing the use of matrices and determinants. It begins with basic concepts‚ such as Gaussian elimination and matrix representation of systems. The properties and calculations of determinants are thoroughly covered‚ including expansion by minors and cofactor methods. Practical applications in engineering and physics are highlighted‚ demonstrating how these tools solve real-world problems. The section also introduces inverse matrices and their role in solving systems of equations. Exercises and examples are designed to build proficiency in handling linear systems‚ making this chapter essential for students in technical and STEM fields. The content aligns with the SI version‚ ensuring relevance to international standards and applications.

Quadratic Equations and Factoring

This chapter delves into quadratic equations and factoring techniques‚ essential for solving polynomial expressions. It covers factoring methods for various polynomials‚ including difference of squares and sum/difference of cubes. The quadratic formula is introduced‚ along with completing the square and graphing quadratic functions. Applications in engineering and physics illustrate real-world uses of these concepts. Practice problems emphasize solving quadratic equations and factoring‚ preparing students for advanced topics in calculus and technical fields. The SI version ensures content aligns with international standards‚ making it a valuable resource for STEM learners. Clear explanations and practical examples enhance understanding and problem-solving skills.

Exponents‚ Radicals‚ and Vectors

This chapter explores the properties and applications of exponents‚ radicals‚ and vectors in technical mathematics. It covers exponent rules‚ including negative and fractional exponents‚ and simplifies radical expressions. Vectors are introduced with operations like addition‚ subtraction‚ and scalar multiplication. Applications in engineering and physics demonstrate practical uses. Clear examples and exercises help students master these foundational concepts.

Graphs of Trigonometric Functions

This chapter focuses on understanding and analyzing the graphs of essential trigonometric functions‚ including sine‚ cosine‚ and tangent. It explores their periodicity‚ amplitude‚ and phase shifts‚ providing a clear visual representation of how these functions behave. The section also delves into vertical shifts and their impact on graph shapes. Real-world applications‚ such as modeling sound waves or seasonal variations‚ are highlighted to demonstrate the practical relevance of these concepts. The 11th Edition enhances learning with full-color graphs and interactive tools‚ making complex relationships more accessible. Students gain a solid foundation for solving trigonometric equations and interpreting their graphical representations in technical and STEM contexts.

Calculus Fundamentals

Covers essential calculus concepts‚ introducing limits‚ differentiation‚ and integration. These principles are applied to solve technical and real-world problems‚ forming a solid foundation for advanced STEM studies.

Limits form the cornerstone of calculus‚ enabling the study of functions’ behavior as inputs approach specific values. This section introduces the concept of limits‚ explaining their importance in understanding continuity‚ asymptotic behavior‚ and infinity. Students learn to evaluate limits graphically‚ numerically‚ and algebraically‚ with a focus on one-sided limits and infinite limits. The formal definition of a limit is presented‚ along with strategies for solving limit problems‚ such as factoring‚ canceling‚ and L’Hôpital’s Rule for indeterminate forms. Practical applications in engineering and physics illustrate the relevance of limits in real-world problem-solving. This foundational knowledge prepares students for advanced topics like derivatives and integrals.

Basic Differentiation Techniques

Basic differentiation techniques are essential in calculus for understanding rates of change and slopes of functions. The power rule‚ product rule‚ quotient rule‚ and chain rule are fundamental methods taught in the 11th Edition. These techniques enable students to differentiate various functions‚ including polynomials‚ trigonometric‚ and exponential functions. The derivative’s definition as a limit is explored‚ along with its graphical interpretation. Applications in engineering and physics demonstrate how differentiation models real-world phenomena‚ such as velocity and acceleration. Practical examples and exercises help students master these techniques‚ preparing them for advanced calculus topics and technical problem-solving.

Integration Principles

Integration principles form the cornerstone of calculus‚ enabling the calculation of areas under curves and accumulation processes. The 11th Edition explores indefinite integrals‚ definite integrals‚ and the Fundamental Theorem of Calculus‚ linking integration and differentiation. Key techniques such as substitution and integration by parts are thoroughly covered‚ alongside applications in physics and engineering. Students learn to compute volumes‚ work‚ and other real-world quantities using integral calculus. The text emphasizes problem-solving with practical examples‚ ensuring a deep understanding of how integration models accumulation and change in technical and STEM contexts. This foundation is crucial for advanced topics and applying calculus to solve complex problems effectively.

Technical Applications in Various Fields

Technical applications in various fields are emphasized‚ showcasing how mathematical concepts are applied in engineering‚ physics‚ and real-world problem-solving scenarios.

Engineering Applications

The 11th Edition emphasizes engineering applications‚ providing practical examples that illustrate how mathematical concepts are applied in real-world engineering scenarios; Students learn to solve problems related to force systems‚ electrical circuits‚ and material stress‚ among others. The text bridges the gap between theory and practice‚ ensuring that engineering students can apply algebra‚ trigonometry‚ and calculus to design and analysis challenges. These applications are drawn from various engineering disciplines‚ including mechanical‚ electrical‚ and civil engineering‚ making the content relevant and engaging for future professionals. By focusing on practical problem-solving‚ the book prepares students to tackle complex engineering tasks with confidence.

Physics and Technology Applications

The 11th Edition integrates mathematical concepts with practical physics and technology applications‚ demonstrating how algebra‚ trigonometry‚ and calculus solve real-world problems. Topics include motion analysis‚ force systems‚ and energy calculations‚ providing students with a solid foundation for understanding physical phenomena. The text also explores applications in technology‚ such as electrical circuits‚ wave analysis‚ and digital signal processing. These examples highlight the relevance of technical mathematics in advancing scientific and technological innovations. By connecting mathematical principles to their practical use‚ the book equips students with the skills to analyze and solve problems in physics and technology effectively‚ preparing them for careers in research and development.

Real-World Problem Solving

The 11th Edition emphasizes real-world problem-solving by connecting mathematical concepts to practical scenarios in engineering and technology. Students learn to apply algebra‚ trigonometry‚ and calculus to solve challenges in fields like engineering design‚ robotics‚ and environmental science. The text includes case studies and projects that simulate professional tasks‚ fostering critical thinking and teamwork. By mastering these problem-solving techniques‚ students gain the ability to analyze complex situations‚ develop innovative solutions‚ and implement them effectively. This approach prepares learners for the demands of technical careers‚ where mathematical proficiency and problem-solving skills are essential for success. The integration of real-world applications ensures that students understand the practical relevance of the mathematics they are learning.

Supplementary Resources and Tools

The 11th Edition provides a Test Bank‚ MyMathLab access‚ and online tutorials with video lectures to enhance learning and mastery of technical mathematics concepts.

Test Bank and MyMathLab Access

The 11th Edition provides an extensive Test Bank with multiple-choice and free-response questions‚ ensuring comprehensive self-assessment. MyMathLab access enhances learning with interactive tutorials‚ homework tools‚ and video lectures tailored to the textbook content. These resources support personalized study‚ offering real-time feedback and adaptive learning paths to improve understanding of technical mathematics and calculus concepts. The Test Bank and MyMathLab integration allow students to practice problem-solving‚ review challenging topics‚ and track their progress effectively. These supplementary tools are designed to complement the textbook‚ making learning more engaging and accessible for STEM students.

Online Tutorials and Video Lectures

The 11th Edition includes online tutorials and video lectures that provide step-by-step explanations for key mathematical concepts. These resources cover topics from algebraic operations to calculus‚ offering visual and auditory learning aids. Videos demonstrate problem-solving techniques‚ while interactive simulations allow students to explore complex concepts in a dynamic environment. Accessible through MyMathLab‚ these tools cater to diverse learning styles‚ enabling students to review material at their own pace. They are particularly helpful for understanding difficult topics like limits‚ differentiation‚ and integration. The combination of tutorials and video lectures ensures that students can reinforce their understanding of technical mathematics and calculus outside the classroom. This feature enhances the overall learning experience‚ making it more flexible and effective.

Publisher and Publication Details

Published by Pearson‚ the 11th Edition of Basic Technical Mathematics with Calculus SI Version is authored by Allyn J. Washington and Michelle Boué‚ with ISBN 978-0-134-27628-3.

Publication History and Edition Updates

The 11th Edition of Basic Technical Mathematics with Calculus SI Version builds on the legacy of its predecessors‚ with the first edition laying the groundwork for technical math education. Over the years‚ the text has evolved to incorporate modern pedagogical approaches and real-world applications. The 10th edition‚ authored by Allyn J. Washington and Michelle Boué‚ introduced significant updates‚ while the 11th edition features contributions from new co-author Rich Evans. This latest version includes a full-color design‚ enhanced clarity‚ and revised content based on user feedback. Published by Pearson‚ it remains a cornerstone for technical and STEM education‚ ensuring students are well-prepared for industrial and technological challenges.

ISBN and Cataloging Information

The 11th Edition of Basic Technical Mathematics with Calculus SI Version is identified by its ISBN-10: 978-0-13-276283 and ISBN-13: 978-0-13-482911. Published by Pearson‚ this edition is cataloged under mathematics textbooks for technical and STEM education. The ISBN ensures easy identification and access to the book globally‚ while the cataloging information aligns it with academic resources. This edition reflects updates in content and pedagogy‚ making it a reliable resource for students and educators in technical fields. The ISBN system helps libraries‚ retailers‚ and learners locate the book efficiently‚ ensuring its availability for coursework and professional development.

Target Audience and Course Duration

This textbook is designed for students in technical and STEM fields‚ ideal for two to three-semester courses. It serves both undergraduate students and professionals seeking foundational math skills.

Appropriate for Two to Three-Semester Courses

The 11th Edition of Basic Technical Mathematics with Calculus SI Version is specifically designed for a two to three-semester course structure. It provides a comprehensive yet structured approach‚ making it ideal for undergraduate students and professionals in technical and STEM fields. The textbook covers foundational topics such as algebra‚ trigonometry‚ and calculus‚ ensuring a gradual progression of complexity. Its full-color design and enhanced pedagogy‚ including relevant applications‚ make complex concepts accessible. The inclusion of real-world problem-solving examples aligns with practical job requirements‚ preparing students for professional challenges. With its logical organization and clear explanations‚ this edition supports a balanced learning experience over multiple semesters‚ ensuring mastery of essential mathematical skills for technical applications.

Suitable for Technical and STEM Fields

The 11th Edition of Basic Technical Mathematics with Calculus SI Version is tailored to meet the demands of technical and STEM disciplines. It emphasizes practical applications‚ ensuring students understand how mathematical concepts apply to real-world problems in engineering‚ physics‚ and technology. The text integrates algebra‚ trigonometry‚ and calculus seamlessly‚ aligning with the curriculum needs of technical programs. Enhanced pedagogy‚ including full-color visuals and relevant examples‚ supports learning in fields requiring precise mathematical skills. This edition is particularly beneficial for students pursuing careers in engineering‚ physics‚ and other STEM-related professions‚ as it bridges theory with practical‚ job-related scenarios to prepare them for professional challenges.