Kubota wiring diagrams are essential for understanding electrical systems in tractors and equipment. They provide detailed layouts for troubleshooting‚ repairs‚ and installations‚ available in official manuals and online platforms.

1.1 Importance of Wiring Diagrams for Kubota Equipment

Kubota wiring diagrams are crucial for diagnosing and repairing electrical issues in tractors and equipment. They provide a visual representation of the electrical system‚ ensuring safe and efficient troubleshooting. By following these diagrams‚ users can identify faulty components‚ understand circuit connections‚ and perform precise repairs. This reduces downtime and prevents potential safety hazards. Additionally‚ wiring diagrams are essential for installing new electrical components‚ ensuring compatibility and proper functionality. They also help technicians adhere to manufacturer standards‚ maintaining the integrity of the equipment. Regular reference to these diagrams ensures optimal performance and longevity of Kubota machinery.

1.2 Overview of Kubota Wiring Diagram PDFs

Kubota wiring diagram PDFs are comprehensive guides that provide detailed electrical system layouts for various Kubota tractor models and utility vehicles. These PDFs cover models such as the B Series‚ M Series‚ and RTV Series‚ offering clear visual representations of wiring connections‚ components‚ and circuits. They include symbols‚ color coding‚ and connector information to ensure accurate diagnostics and repairs. Available through official Kubota service manuals‚ online platforms‚ and third-party websites‚ these PDFs are indispensable for technicians and operators. They enable safe and efficient troubleshooting‚ ensuring proper functionality and longevity of Kubota equipment.

Understanding Kubota Wiring Diagrams

Understanding Kubota wiring diagrams is essential for diagnosing and repairing electrical systems. They detail components‚ symbols‚ and connections‚ enabling users to identify and resolve issues efficiently.

2.1 Components of a Kubota Wiring Diagram

A Kubota wiring diagram typically includes various components such as power sources‚ switches‚ sensors‚ connectors‚ and fuses. These elements are represented through symbols and labels‚ making it easier to identify and trace electrical circuits. The diagram also outlines the flow of electricity‚ showcasing how different parts of the system interconnect. For example‚ it may detail the alternator‚ ignition switch‚ and fuel sensors‚ along with their respective wiring paths. Additionally‚ it highlights critical components like relays‚ circuit breakers‚ and grounding points. Understanding these components is crucial for diagnosing and repairing electrical issues efficiently.

2.2 Symbols and Notations Used in Wiring Diagrams

Kubota wiring diagrams utilize a variety of symbols and notations to represent electrical components and connections. These symbols are standardized‚ ensuring consistency across different models. Common symbols include representations for batteries‚ switches‚ fuses‚ relays‚ and grounding points. Lines and arrows indicate the flow of electrical current‚ while color coding highlights different circuits. Notations such as “VB” for voltage supply or “GND” for ground help technicians interpret the diagram accurately. Understanding these symbols is crucial for navigating the wiring system‚ diagnosing issues‚ and performing repairs effectively. The diagrams also include legends or keys to decode the symbols‚ ensuring clarity and precision in electrical work.

2.3 Color Coding in Kubota Wiring Diagrams

Color coding in Kubota wiring diagrams is a critical tool for identifying and understanding electrical circuits. Wires are color-coded to differentiate between power supply‚ ground‚ and signal lines. For instance‚ red wires often indicate positive voltage‚ while black wires signify ground or negative paths. Yellow wires may denote warning or signal circuits‚ and blue wires could represent control or accessory systems. This standardized approach ensures technicians can quickly trace and diagnose issues. Properly interpreting these colors is essential for safe and accurate electrical repairs. The diagrams frequently include a legend explaining the color codes‚ making it easier to navigate complex systems efficiently.

How to Read a Kubota Wiring Diagram

Start by identifying the layout‚ focusing on components and symbols. Trace circuits systematically‚ using color codes and legends for clarity. Cross-reference with service manuals for accuracy.

3.1 Identifying the Layout of the Diagram

Begin by examining the overall structure of the Kubota wiring diagram. Typically‚ diagrams are organized into sections‚ such as power supply‚ control circuits‚ and output components. Locate the main power source‚ usually depicted at the top or left side‚ and trace how it connects to various parts. Identify key components like fuses‚ relays‚ and connectors‚ which are often highlighted in distinct areas. The layout may also include a legend or key explaining symbols and abbreviations‚ ensuring clarity for users. Understanding this structure helps in navigating the diagram efficiently for repairs or installations.

3.2 Understanding Electrical Connectors and Terminals

Electrical connectors and terminals in Kubota wiring diagrams are crucial for secure and reliable connections. Connectors are color-coded or labeled to indicate their function‚ such as power‚ ground‚ or signal lines. Terminals are often marked with abbreviations like “B” for battery or “G” for ground. The diagrams detail how these components link to ensure proper circuit flow. Identifying the correct connector type‚ such as spade‚ butt‚ or ring connectors‚ is essential for repairs. Always refer to the legend or key in the diagram for accurate identification. Properly matching connectors and terminals prevents electrical faults and ensures safe operation of the equipment.

3.3 Troubleshooting Using a Wiring Diagram

Troubleshooting with a Kubota wiring diagram involves identifying faulty circuits or components by tracing electrical paths. Start by isolating the affected system‚ then cross-reference the diagram to locate connectors and terminals. Use tools like multimeters to test voltage and continuity. Look for signs of damage‚ such as frayed wires or corroded connectors. The diagram helps pinpoint where issues like short circuits or open connections may occur. By systematically checking each component‚ you can diagnose and repair electrical problems efficiently. Always follow safety protocols and consult the diagram for specific repair procedures to ensure accurate and safe troubleshooting.

Safety Precautions When Working with Kubota Wiring

Always disconnect power before working on Kubota wiring. Use insulated tools‚ avoid short circuits‚ and wear protective gear. Follow manual guidelines to ensure safe electrical system handling.

4.1 Essential Safety Tools and Equipment

When working with Kubota wiring‚ essential safety tools include insulated screwdrivers‚ pliers‚ and wrenches to prevent electric shock. A multimeter is crucial for voltage testing‚ ensuring circuits are de-energized. Protective gear like gloves‚ safety glasses‚ and a fire-resistant apron should always be worn. A voltage tester helps verify power absence‚ while wire strippers and crimpers aid in safe connections. Proper lighting ensures visibility‚ and a first aid kit is vital for emergencies. Using the correct tools prevents damage to wiring and ensures compliance with safety standards. Always refer to the Kubota wiring diagram PDF for specific guidelines on tool usage and equipment requirements.

4.2 Best Practices for Handling Electrical Systems

Always refer to the Kubota wiring diagram PDF and service manuals for specific instructions. Disconnect power before starting any electrical work to prevent shocks. Use multimeters and voltage testers to ensure circuits are de-energized. Avoid touching live wires and components to prevent electric shock. Regularly inspect wiring for damage or wear‚ addressing issues promptly. Ground equipment properly to maintain safety. Follow manufacturer guidelines for tool usage and repairs. Test circuits cautiously and verify connections before restoring power. Stay informed about potential hazards and updates in wiring systems. By adhering to these practices‚ you ensure safe and effective troubleshooting and maintenance of Kubota electrical systems.

4.3 Common Hazards in Electrical Wiring

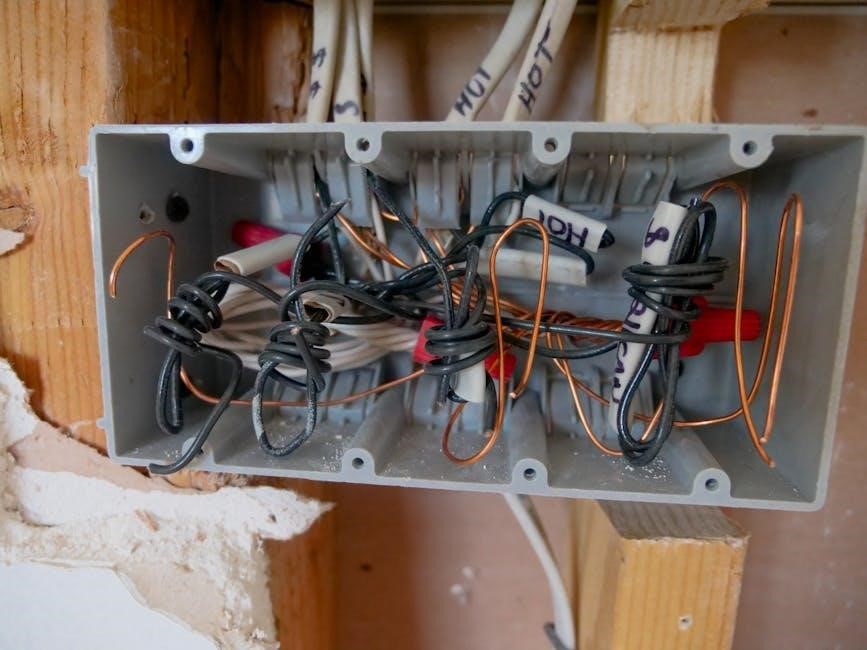

Common hazards in Kubota wiring include short circuits‚ overloaded circuits‚ and faulty connectors. Arcing from damaged wires or connectors can cause fires; Exposed or frayed wiring increases the risk of electric shock. Improper grounding leads to unsafe voltage levels. Corrosion in connectors and terminals disrupts electrical flow. Overheating components indicate potential failures. Misaligned or loose connections cause intermittent issues. Voltage fluctuations damage sensitive electronics. Always inspect wiring for wear and ensure proper installation to minimize risks. Regular maintenance and adherence to safety protocols are crucial for preventing accidents and ensuring reliable operation of Kubota equipment. Addressing these hazards promptly is essential for operator safety and system longevity;

Sources for Kubota Wiring Diagrams

Kubota wiring diagrams are available through official service manuals‚ online platforms‚ and third-party resources‚ covering models like B Series and M Series tractors for DIY repairs.

5.1 Official Kubota Service Manuals

Official Kubota service manuals are the most reliable source for wiring diagrams‚ offering detailed schematics and component information. They cover various tractor models‚ including the B Series‚ M Series‚ and RTV utility vehicles. These manuals are designed to help technicians and operators understand and repair electrical systems accurately. Available in PDF format‚ they provide clear layouts of circuits‚ connectors‚ and terminals. By referencing these manuals‚ users can ensure compliance with manufacturer specifications‚ reducing the risk of errors during repairs or upgrades. Official manuals are accessible through Kubota dealerships or authorized online platforms‚ making them a trustworthy resource for electrical work.

5.2 Online Platforms for Wiring Diagrams

Online platforms offer a wealth of Kubota wiring diagrams‚ accessible in PDF format for easy download. Websites like Truck-Manuals.Net provide free resources‚ including diagrams for models such as the B20‚ B21‚ and B1700. These platforms often cater to specific tractor series‚ ensuring users find relevant schematics quickly. Additionally‚ forums and specialized automotive sites share detailed wiring diagrams‚ covering electrical systems for Kubota engines and utility vehicles. Online resources are convenient‚ saving time and effort compared to traditional manual searches. However‚ users should verify the authenticity and compatibility of diagrams with their equipment to ensure accuracy and safety during repairs or modifications.

5.3 Third-Party Resources and Websites

Beyond official sources‚ third-party websites and forums provide accessible Kubota wiring diagrams. Platforms like GitHub host user-contributed diagrams‚ while specialized forums offer shared resources. These sites often include community discussions‚ offering insights and tips from experienced users. Third-party resources may also include DIY guides and custom wiring solutions. However‚ users should exercise caution‚ as diagrams may vary in accuracy and completeness. Always verify the source and cross-reference with official manuals to ensure reliability. Third-party resources can be invaluable for unique or older Kubota models‚ offering affordable or free access to essential wiring information for repairs and modifications.

Common Mistakes to Avoid

Common mistakes include misinterpreting wiring symbols‚ ignoring safety protocols‚ and using incorrect tools‚ which can lead to electrical hazards or faulty repairs. Always follow guidelines carefully.

6.1 Misinterpreting Wiring Diagram Symbols

Misinterpreting wiring diagram symbols is a common mistake that can lead to incorrect connections and electrical issues. Each symbol represents specific components or functions‚ such as switches‚ fuses‚ or relays. Incorrectly identifying these can result in faulty repairs or system malfunctions. To avoid this‚ always cross-reference symbols with the legend provided in the Kubota wiring diagram PDF. Pay attention to color coding and notation conventions‚ as they vary between models. Using outdated diagrams or failing to recognize updates can also cause confusion. Ensure all symbols are understood before proceeding with any electrical work to maintain safety and system integrity.

6.2 Overlooking Safety Protocols

Overlooking safety protocols when working with Kubota wiring diagrams can lead to serious risks‚ including electrical shocks‚ injuries‚ and equipment damage. Always disconnect power sources before starting work and use insulated tools to prevent accidental contact with live wires. Failing to ground systems properly or neglecting to wear protective gear can exacerbate hazards. Additionally‚ ignoring manufacturer guidelines for voltage testing or component handling can result in costly repairs or safety breaches. Prioritize safety by following best practices‚ such as de-energizing circuits and ensuring proper ventilation in work areas. Never skip precautionary steps‚ as they are critical for safe and effective electrical system maintenance.

6.3 Using Incorrect Tools for Wiring Repairs

Using incorrect tools for wiring repairs can damage components‚ compromise safety‚ and lead to improper connections. Avoid using standard screwdrivers‚ as they may not insulate against electrical shocks. Incorrect wire strippers can strip too much insulation‚ exposing conductors and risking short circuits. Pliers or plugging tools that don’t fit connectors properly can bend or break terminals. Always use tools specifically designed for electrical work‚ such as insulated screwdrivers and precision wire strippers. Consult the Kubota wiring diagram or service manual for recommended tools to ensure safe and effective repairs. Improper tools can void warranties or cause further electrical issues‚ emphasizing the need for precision and care.

Best Practices for Using Kubota Wiring Diagrams

Always refer to official service manuals for accuracy. Cross-reference diagrams with repair guides for comprehensive understanding. Ensure model-specific diagrams are used for precise repairs. Regularly update diagrams and use proper tools to avoid errors.

7.1 Regular Updates and Revisions

Regularly updating your Kubota wiring diagrams ensures accuracy and compatibility with the latest equipment. Manufacturers often release revised diagrams to reflect design changes or improvements. Always check Kubota’s official website or authorized dealers for the most recent versions. Outdated diagrams can lead to errors in troubleshooting or installations. Additionally‚ subscribe to Kubota’s newsletters or forums for notifications about updates. Keeping your wiring diagrams current is crucial for maintaining efficiency and safety in repairs and upgrades. This practice also helps in identifying new components or connectors introduced in updated models. Never rely on outdated diagrams‚ as they may not align with your specific equipment configuration.

7.2 Cross-Referencing with Service Manuals

Cross-referencing Kubota wiring diagrams with service manuals ensures comprehensive understanding of electrical systems. Service manuals provide detailed explanations of components‚ troubleshooting guides‚ and repair procedures. Wiring diagrams‚ when used alongside these manuals‚ help pinpoint issues and identify correct repair methods. For example‚ a diagram may show a faulty connector‚ while the manual explains replacement steps. This combination is essential for accurate diagnostics and efficient repairs. Always verify the compatibility of diagrams with your specific Kubota model‚ as variations exist across different tractors and equipment. This dual approach minimizes errors and ensures compliance with manufacturer guidelines for electrical system maintenance.

7.3 Consulting Professionals for Complex Issues

For complex electrical issues in Kubota equipment‚ consulting professionals is highly recommended. Experienced technicians possess in-depth knowledge of wiring diagrams and systems‚ ensuring accurate diagnoses and repairs. They can interpret complex diagrams‚ identify hidden faults‚ and apply specialized tools effectively. DIY attempts without proper expertise may lead to further damage or safety hazards. Professionals also have access to updated manuals and resources‚ ensuring compliance with manufacturer standards. For critical issues like faulty ECUs or intricate wiring faults‚ consulting a certified Kubota technician is the best approach to avoid prolonged downtime and ensure reliable operation. This expertise is invaluable for maintaining your equipment’s performance and longevity.

Popular Kubota Models and Their Wiring Diagrams

Popular Kubota models like the B Series‚ M Series‚ and RTV Series have detailed wiring diagrams available in PDF formats for easy reference and troubleshooting.

8.1 Kubota B Series Tractors

Kubota B Series tractors‚ including models like B1550‚ B1700‚ and B2100‚ have comprehensive wiring diagrams available in PDF format. These diagrams detail electrical systems‚ components‚ and connections‚ aiding in troubleshooting and repairs. They cover circuits for ignition‚ lighting‚ and accessories‚ ensuring clarity for maintenance and upgrades. The diagrams are accessible through official Kubota service manuals and trusted online platforms‚ providing users with accurate and reliable information. By referencing these resources‚ operators can efficiently diagnose and resolve electrical issues‚ ensuring optimal tractor performance. Safety and accuracy are prioritized in these documents‚ making them indispensable for both professionals and DIY enthusiasts working on Kubota B Series tractors.

8.2 Kubota M Series Tractors

Kubota M Series tractors‚ such as the M4700‚ are supported by detailed wiring diagrams in PDF format. These diagrams outline the electrical systems‚ including circuits for ignition‚ lighting‚ and accessories‚ aiding in repairs and upgrades. They are available through official Kubota service manuals and trusted online platforms‚ ensuring accurate information for troubleshooting and maintenance. The diagrams cover essential components‚ helping users identify and resolve electrical issues efficiently. Whether for routine maintenance or complex repairs‚ these resources are invaluable for maintaining optimal tractor performance. They are designed to assist both professional technicians and DIY enthusiasts in understanding and working with Kubota M Series electrical systems effectively.

8.3 Kubota RTV Series Utility Vehicles

Kubota RTV Series utility vehicles have specific wiring diagrams available in PDF format‚ detailing their electrical systems. These diagrams cover essential components like headlights‚ winches‚ and accessories‚ aiding in troubleshooting and repairs. They are accessible through official Kubota manuals and online platforms‚ ensuring accuracy and reliability. The diagrams help users identify circuits‚ connectors‚ and wiring routes‚ making it easier to diagnose and fix issues. Whether for maintenance or upgrades‚ these resources are crucial for optimizing performance. They cater to both professionals and enthusiasts‚ providing a clear guide to understanding and working with the electrical systems of Kubota RTV Series utility vehicles effectively and safely.

Customizing Your Kubota Wiring Diagram

Customizing Kubota wiring diagrams allows for personalized electrical system upgrades. Users can add components‚ modify circuits‚ and document changes for enhanced functionality and compatibility with aftermarket parts or accessories.

9.1 Adding Custom Electrical Components

Adding custom electrical components to your Kubota wiring diagram enhances functionality and performance. Start by identifying the component’s purpose and ensuring compatibility with existing systems. Consult the official Kubota wiring diagram to locate suitable connection points and plan the circuit layout. Use high-quality‚ Kubota-approved parts to maintain reliability and safety. When installing‚ follow proper wiring techniques and secure connections to prevent electrical failures. Always test the system post-installation to ensure proper operation. For complex modifications‚ consider consulting a professional to avoid potential risks. Documenting changes in your wiring diagram helps future maintenance and troubleshooting. Regular inspections are crucial to uphold system integrity and performance.

9.2 Modifying Existing Wiring for Upgrades

Modifying existing wiring for upgrades requires careful planning and precision. Always consult the Kubota wiring diagram to identify the components involved and plan the upgrade layout. Ensure compatibility by selecting parts that align with Kubota’s specifications. Disconnect the battery and use proper tools to avoid electrical shocks or damage. When rerouting or splicing wires‚ follow Kubota’s recommended practices to maintain system integrity. Test the upgraded system thoroughly to ensure proper functionality. Document all changes in your wiring diagram for future reference. Improper modifications can lead to system malfunctions or safety hazards‚ so precision is critical. Regular inspections post-upgrade are essential to ensure long-term reliability and performance.

9.3 Documenting Custom Changes

Documenting custom changes is crucial for maintaining clarity and ensuring future compatibility. After modifying the wiring‚ update your Kubota wiring diagram to reflect all alterations. Use clear labels and notes to detail what was changed‚ why‚ and how. Include before-and-after diagrams if possible‚ and store the updated document in an accessible format‚ such as PDF. This ensures that anyone working on the system in the future can understand the custom setup. Regularly review and update the documentation to reflect new modifications. Proper documentation prevents confusion‚ reduces errors‚ and simplifies future troubleshooting or upgrades. It also helps maintain the system’s integrity and safety over time.

Troubleshooting Electrical Issues

Using Kubota wiring diagrams‚ identify faulty components and connectors. Utilize multimeters to diagnose electrical faults and repair damaged wiring to restore system functionality effectively.

10.1 Identifying Faulty Wiring or Connectors

Kubota wiring diagrams are crucial for pinpointing faulty wiring or connectors. Begin with a visual inspection‚ looking for signs of wear‚ corrosion‚ or physical damage. Use a multimeter to check for continuity and voltage drops across suspected circuits. Cross-reference the wiring diagram to identify where power should flow and compare it with actual readings. Common issues include loose connections‚ damaged insulation‚ or malfunctioning terminals. For Kubota tractors‚ pay special attention to high-current circuits like alternators and starter motors. Systematic troubleshooting using the diagram ensures accurate identification of faults‚ reducing downtime and repair costs. Always follow safety protocols when handling live electrical systems.

10.2 Using Multimeters for Diagnosis

A multimeter is an essential tool for diagnosing electrical issues in Kubota equipment; It measures voltage‚ current‚ and resistance‚ helping to identify faulty wiring or components. Set the multimeter to DCV for checking battery voltage or DCA for current flow. Use the wiring diagram to locate test points and compare readings with expected values. For example‚ test continuity between connectors to detect open circuits or check for short circuits by measuring unintended voltage. Always disconnect the battery before testing to ensure safety. By following the wiring diagram and using a multimeter‚ you can isolate issues efficiently and perform accurate repairs on Kubota electrical systems.

10.3 Repairing Damaged Wiring

Repairing damaged wiring in Kubota equipment requires precision and adherence to the wiring diagram. Start by identifying the faulty section using the diagram‚ then disconnect the power source for safety. Use wire strippers to remove damaged insulation and clean the wires. Apply solder or crimp connectors to join the wires securely. Insulate the repaired area with heat-shrink tubing or electrical tape. For complex repairs‚ refer to the official Kubota service manual or consult a professional. Always test the circuit with a multimeter after repairs to ensure proper connectivity and voltage flow. Properly documented repairs ensure future troubleshooting is efficient and reliable.

Kubota wiring diagrams are essential for efficient troubleshooting and repairs. They ensure safety and reliability‚ making them indispensable for all electrical work on Kubota equipment.

11.1 Summary of Key Points

This guide has covered essential aspects of Kubota wiring diagrams‚ including their importance‚ components‚ and safe usage. Key points emphasize understanding symbols‚ color coding‚ and layout for accurate troubleshooting. Sources like official manuals and online platforms provide reliable diagrams‚ while best practices such as cross-referencing and professional consultation ensure efficiency. Safety precautions and avoiding common mistakes are crucial for effective electrical work. Regular updates and proper documentation are recommended for custom modifications. Troubleshooting techniques‚ including multimeter use‚ help diagnose and repair issues. Always refer to official Kubota manuals for accurate information and consult professionals for complex problems to maintain equipment reliability and performance.

11.2 Final Tips for Working with Kubota Wiring Diagrams

Always verify the source of your Kubota wiring diagrams to ensure accuracy. Prioritize safety by using proper tools and following protocols. Regularly update your diagrams to reflect equipment changes and cross-reference with official manuals. For complex issues‚ consult professionals to avoid costly mistakes. Document custom modifications for future reference. Invest in quality test equipment‚ like multimeters‚ for precise diagnostics. Stay informed about new Kubota models and their wiring systems. By following these tips‚ you can efficiently troubleshoot‚ repair‚ and maintain your Kubota equipment‚ ensuring optimal performance and longevity.